- Introduction to Bare Conductor Cables

Bare conductor cables are a fundamental component in the power transmission and distribution industry. Unlike insulated cables, they lack an insulating layer, making them ideal for outdoor applications such as overhead power lines and substations. These cables are designed to carry electrical current over long distances with minimal energy losses. Below, we explore their functionality, features, advantages, and disadvantages.

Usage Scenarios:

Bare conductor cables are primarily used in:

Overhead power lines: For transmitting electricity across long distances.

Substations: For conducting electricity within electrical grids.

Grounding systems: To ensure safety by providing a path for fault currents.

How They Work:

The primary function of bare conductor cables is to conduct electricity efficiently. They rely on highly conductive materials, typically aluminum or copper, to transmit electrical current. The absence of insulation allows for better heat dissipation and reduces the overall weight of the cable.

Features:

High Conductivity: Materials like copper and aluminum ensure excellent electrical conductivity.

Durability: Designed to withstand harsh environmental conditions, including extreme temperatures and mechanical stress.

Cost-Effective: The lack of insulation reduces manufacturing and material costs.

Easy Installation: Lightweight and flexible, making them easier to install compared to insulated cables.

Disadvantages:

No Protection Against Short Circuits: The absence of insulation increases the risk of short circuits if not properly managed.

Exposure to Environmental Elements: Vulnerable to corrosion, wind, and rain, which can affect performance over time.

Limited Use Cases: Not suitable for applications where insulation is required for safety or operational reasons.

Classification by Material, Function, and Standards

Bare conductor cables can be categorized based on the materials used, their functionality, and the standards they adhere to.

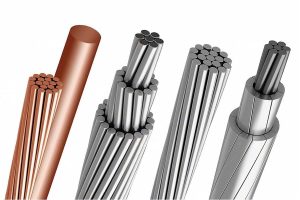

By Material:

Copper: Offers high conductivity and durability but is heavier and more expensive.

Aluminum: Lightweight and cost-effective, though slightly less conductive than copper.

By Function:

Overhead Transmission Lines: Designed for long-distance electricity transmission.

Grounding Wires: Used to ground electrical systems and ensure safety.

Busbars: Conduct electricity within substations and industrial facilities.

By Standards:

IEC Standards: International Electrotechnical Commission standards for global compatibility.

IEEE Standards: Institute of Electrical and Electronics Engineers standards, commonly used in the U.S.

EN Standards: European standards for electrical conductors.

Product Structure and Specifications

Bare conductor cables come in various structures and specifications to meet diverse application needs. Below are some widely used models:

AAC (All Aluminum Conductor):

Structure: Composed of aluminum strands.

Specifications: Available in various diameters and cross-sectional areas. Commonly used in urban areas due to its lightweight.

ACSR (Aluminum Conductor Steel Reinforced):

Structure: Aluminum strands wrapped around a steel core.

Specifications: High tensile strength, ideal for long-span overhead lines.

AAAC (All Aluminum Alloy Conductor):

Structure: Made of aluminum alloy strands.

Specifications: Combines the benefits of AAC and ACSR, offering higher corrosion resistance.

Examples:

AAC “Oak”: Diameter of 10 mm, cross-sectional area of 80 mm², suitable for medium-length transmission lines.

ACSR “Hawk”: Features a steel core with aluminum strands, designed for high-strength, long-span transmission lines.

Production Process, Testing Methods, and Steps

The production of bare conductor cables involves several critical steps to ensure quality and performance.

Production Process:

Material Selection: High-quality aluminum or copper is chosen.

Wire Drawing: Metal rods are reduced in diameter through a series of dies.

Stranding: Multiple wires are twisted together to form the conductor.

Annealing: The conductor is heated and cooled to improve ductility and conductivity.

Testing Methods:

Tensile Strength Test: Ensures the cable can withstand mechanical stresses.

Conductivity Test: Measures electrical conductivity to ensure efficient power transmission.

Corrosion Resistance Test: Evaluates durability in harsh environments.

Visual Inspection: Checks for physical defects and ensures proper stranding.

New Products, Technologies, and Innovations

The bare conductor cable industry is evolving with advancements aimed at improving performance and reliability.

New Products:

High-Temperature Low-Sag (HTLS) Conductors: Operate at higher temperatures with minimal sag, ideal for areas with high thermal loads.

New Technologies:

Composite Core Conductors: Use composite materials for the core, offering high strength and low weight.

Innovations:

Nano-Coating Technology: Enhances corrosion resistance and extends cable lifespan.

Smart Conductors: Embedded sensors enable real-time monitoring of temperature and electrical load.

- Additional Resources

For more detailed information on bare conductor cables, refer to the following resources:

IEEE Standards on Bare Conductors

IEC Standards and Guidelines

European Standards on Electrical Conductors

- Stay Connected

Follow us on YouTube and Facebook to stay updated on the latest developments in the cable industry, including new product launches and informative videos.